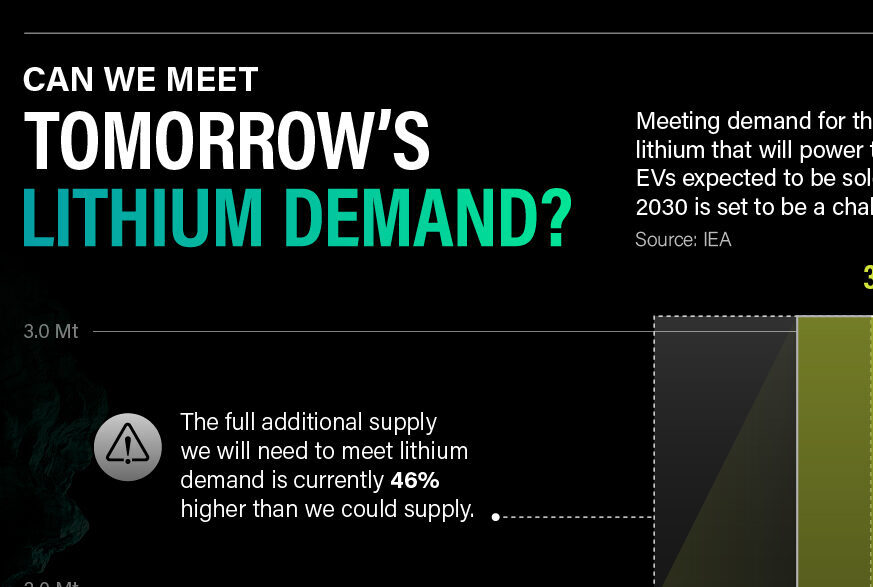

As the world shifts towards sustainable energy solutions, lithium has emerged as a critical natural resource. Its importance is particularly pronounced in the electric vehicle (EV) industry, where lithium-ion batteries are the primary energy storage solution. With projections indicating that over 350 million EVs will be sold globally by 2030, the question arises: can we meet the future demand for lithium?

The Challenge of Meeting Lithium Demand

Lithium is extracted from compounds found in either salt-brine pools or hard rock, and the quantities are measured in terms of lithium carbonate equivalent (LCE). As the adoption of EVs accelerates, so does the demand for lithium. However, the current rate of lithium production is insufficient to meet this growing demand. According to industry forecasts, the annual demand for lithium could grow by up to 20% by 2030. This means that nearly double the current amount of lithium will be required to support the anticipated number of EVs.

The data illustrates this challenge starkly:

- In 2022: The global LCE supply was 750,000 tons, while the demand was 720,000 tons.

- By 2030: The global LCE supply is projected to be 1,640,000 tons, but the demand could reach 3,060,000 tons.

This discrepancy highlights the urgent need to increase lithium production to avoid potential bottlenecks in the EV market and other industries reliant on lithium-ion batteries.

Extracting a Solution: Direct Lithium Extraction (DLE)

One of the primary reasons for the anticipated shortfall in lithium supply is the inefficiency and environmental impact of conventional extraction methods. Traditional lithium extraction is slow, often taking 18 months to process a lithium deposit, and it can cause significant environmental harm. For instance, producing one ton of lithium using conventional methods requires over 2.2 million liters of fresh water, a considerable strain on water resources.

However, a new technique known as direct lithium extraction (DLE) offers a promising solution. DLE is a more efficient and environmentally friendly method of extracting lithium. It boasts a recovery rate of 90%, significantly higher than conventional processes, and can access lithium from previously untapped sources, such as regions in California and the Smackover formation in Arkansas.

One of the most notable advantages of DLE is its speed. It can process a lithium deposit in just two days, a drastic improvement over the 18-month timeframe required by traditional methods. Additionally, DLE uses minimal water, making it a more sustainable option for lithium extraction. This method’s efficiency and reduced environmental impact could be crucial in meeting the future demand for lithium.

The Path Forward: Innovation and Investment

The potential shortfall in lithium supply poses a significant challenge to the global transition to clean energy and the achievement of the United Nations’ sustainable development goals. However, innovative solutions like DLE offer a way forward. Companies at the forefront of this technology, such as EnergyX, are pioneering new methods to increase lithium production sustainably.

Investment in DLE and other advanced extraction technologies is crucial. These innovations not only promise to meet the rising demand for lithium but also ensure that its extraction does not compromise environmental sustainability. As the world moves towards a greener future, securing a stable and sufficient supply of lithium is vital for the continued growth of the EV market and the broader adoption of renewable energy technologies.

Conclusion

The future of lithium demand is a critical issue as the world transitions to sustainable energy. With over 350 million EVs expected to be sold by 2030, the pressure on lithium supply is immense. Traditional extraction methods are unlikely to meet this demand, highlighting the need for innovative solutions like DLE. Companies like EnergyX are leading the way in developing these technologies, offering hope that the gap between supply and demand can be bridged.

To ensure a sustainable future, it is essential to continue investing in and developing advanced extraction methods. This not only addresses the immediate challenge of meeting lithium demand but also supports the broader goals of environmental sustainability and the global transition to clean energy.